Chronology

The history of the Völklingen Ironworks

The history of the Völklingen Ironworks is a success story that has also had its ups and downs. Along with the successes and its position as Germany's biggest producer of iron girders and holder of the most patents in the iron and steel sector in the world, it also had its dark sides, which included Hermann Röchling's proximity to Adolf Hitler and the National Socialists and the use of forced labour in both world wars. The upswing in the years of the economic boom was followed by the decline in the global steel crisis of the 1970s and the renewed flourishing of the Völklingen Ironworks from its inclusion in the UNESCO World Heritage List.

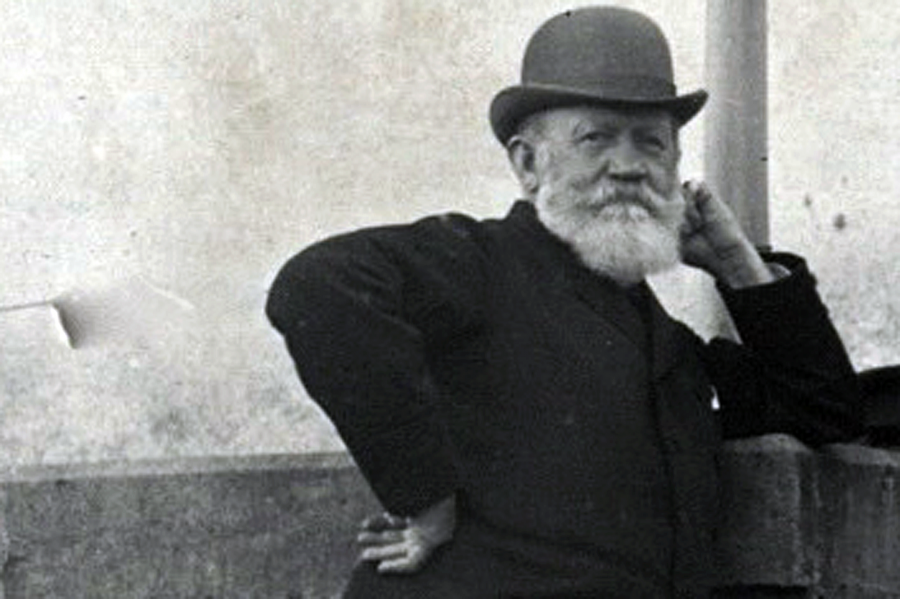

The beginning: Julius Buch

Julius Buch (ca.19XX)

Copyright: Weltkulturerbe Völklinger Hütte | Familie Julius Buch

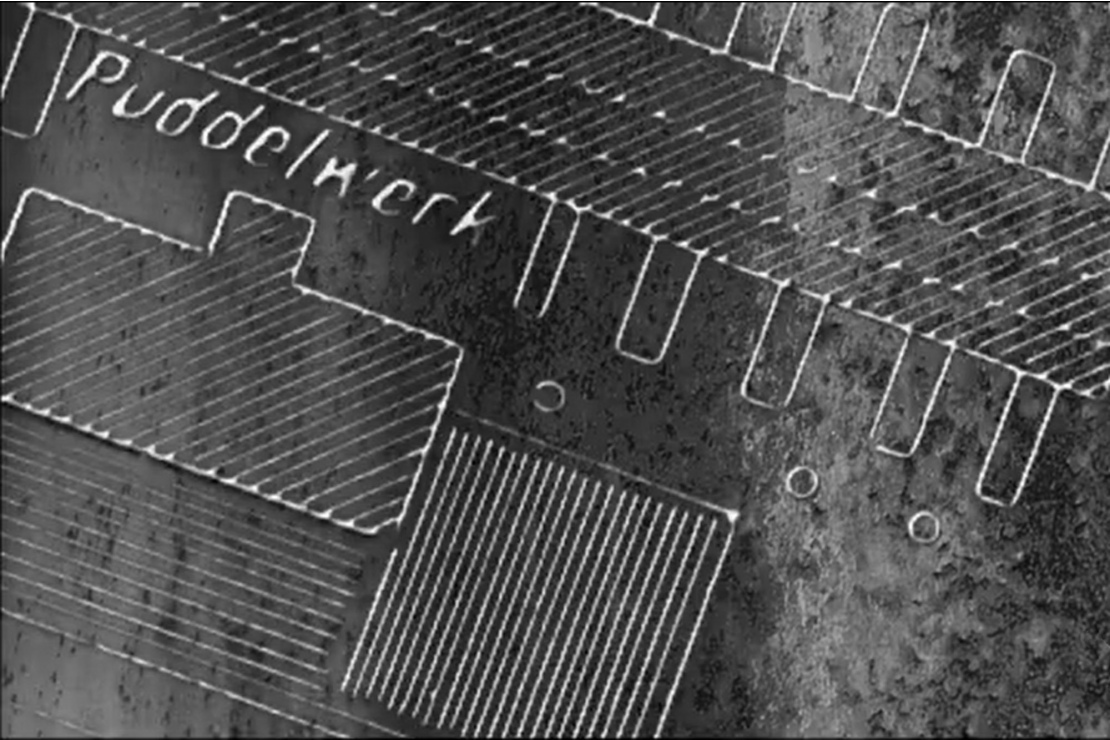

The beginning of a new era: in October 1872, when ironworks engineer Julius Buch in Cologne decided to establish an ironworks on the Saar, he could not have had any idea that he was laying the foundations of more than 100 years of iron and steel production in Völklingen. In the spring of 1873, Buch founded the company 'Völklinger Eisenhütte bei Saarbrücken, Actiengesellschaft für Eisenindustrie' (The Völklingen Ironworks near Saarbrücken, limited company for the iron industry). On 12 May 1873, Julius Buch received the building permit for the construction of the ironworks. By the end of 1873 the works’ 12 puddle furnaces produced bloom iron and iron girders.

At first business was good. But after only five years there was a slump. Import duties were abolished, meaning 'French, Belgian and English iron products could be delivered at a cheaper rate than the old domestic works could produce', as Julius Buch himself was compelled to admit. In December 1878 the works went into liquidation: operations were ceased and all its workers and employees made redundant.

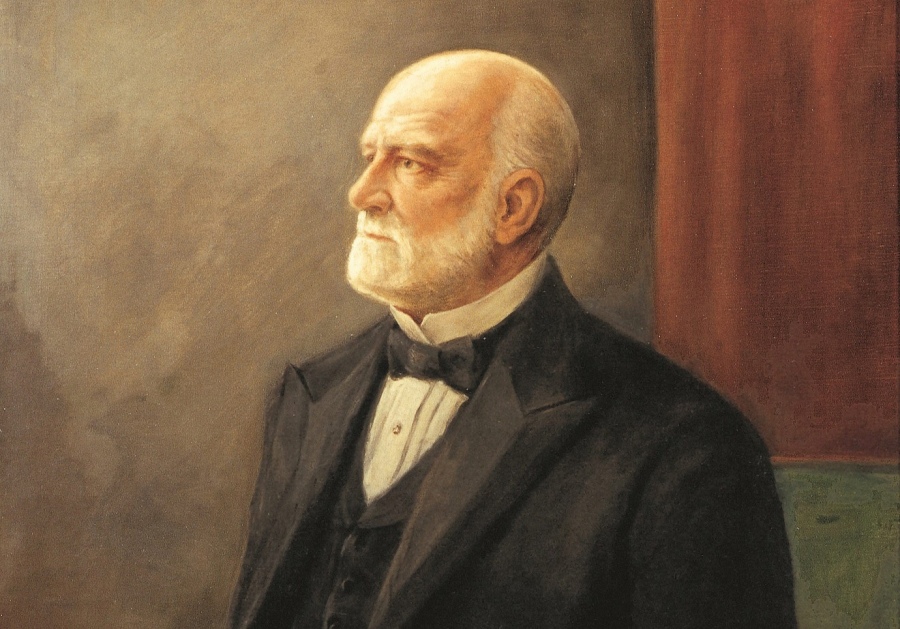

Carl Röchling

Carl, Röchling, Gemälde von Ludwig Würgele

Copyright: Familie Röchling

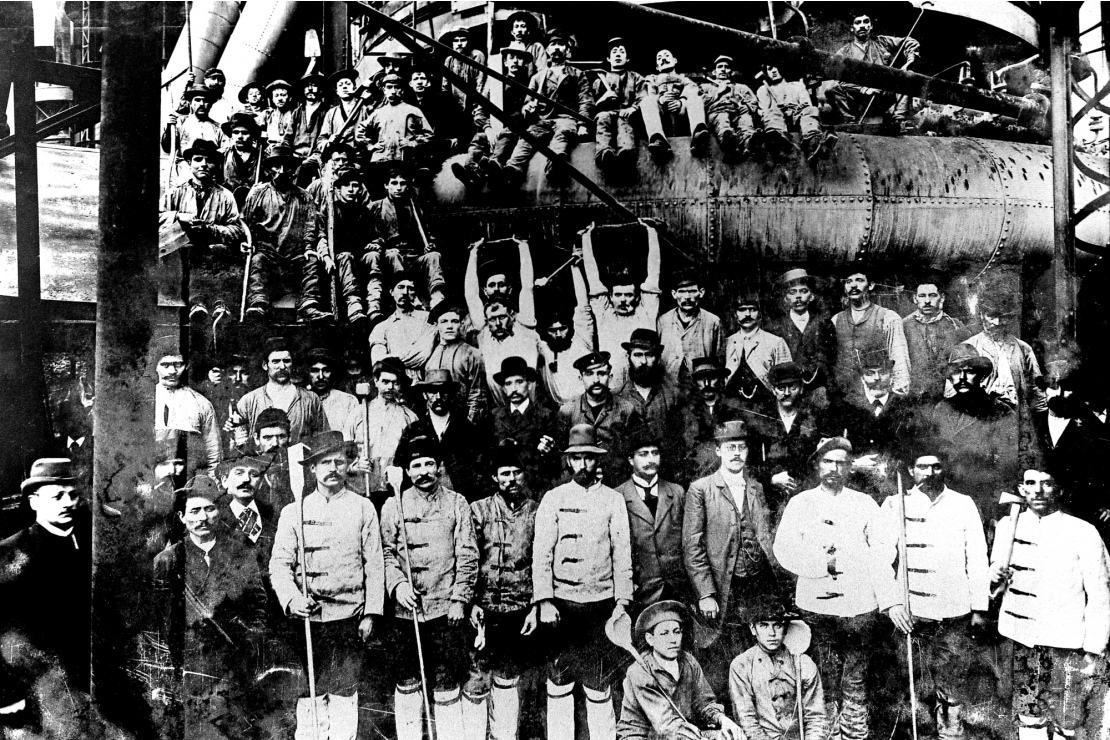

'Dear Theodor, I bought the Völklingen Ironworks yesterday for 270,000 marks…'

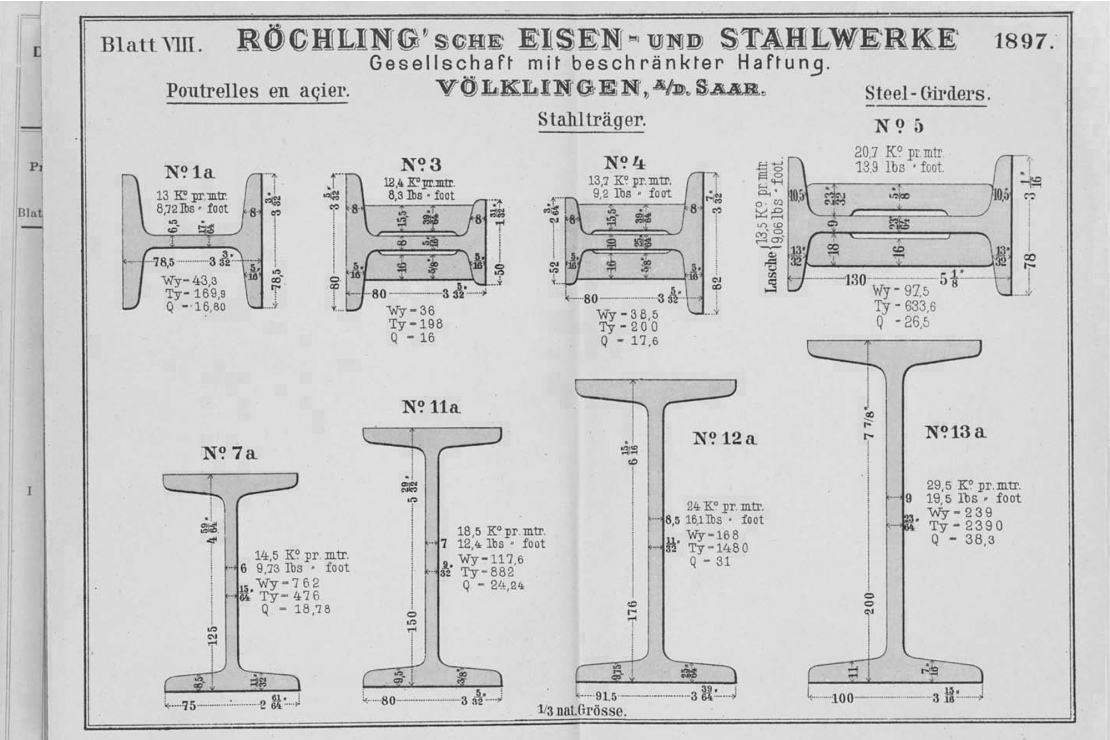

In this telegram, which Carl Röchling sent on 27th August 1881 from Völklingen to his brother Theodor at the parent house of the family in Saarbrücken, he informed him that he had bought the ramschackle Völklingen Ironworks that had recently been put up for auction by the Bros. Haldy company. To supply the Völklingen Ironworks with ore Carl Röchling bought ore fields in Algringen, Lorraine in 1882-1883. Carl Röchling began his development to become an iron and steel industrialist as a merchant involved in commercial and financial capital rather than as an expert and technician. He was very much a 'European' industrialist. He spoke French, he studied in Le Havre and Rotterdam, he ran companies with French business partners and worked closely with French industrialists. Following its prehistory in the depths of bankruptcy Carl Röchling built what became the Röchling‘sche Iron and Steel Works GmbH into one of the highest earning industrial companies of Europe. When the "Geheimer Kommerzienrat" Carl Röchling retired from operational business shortly after the turn of the century, he was one of the wealthiest men of his time. Carl Röchling died in Saarbrücken in 1910.

The First World War

Der Unterstand mit den 4 Kaminen

Copyright: © Mémorial de Verdun

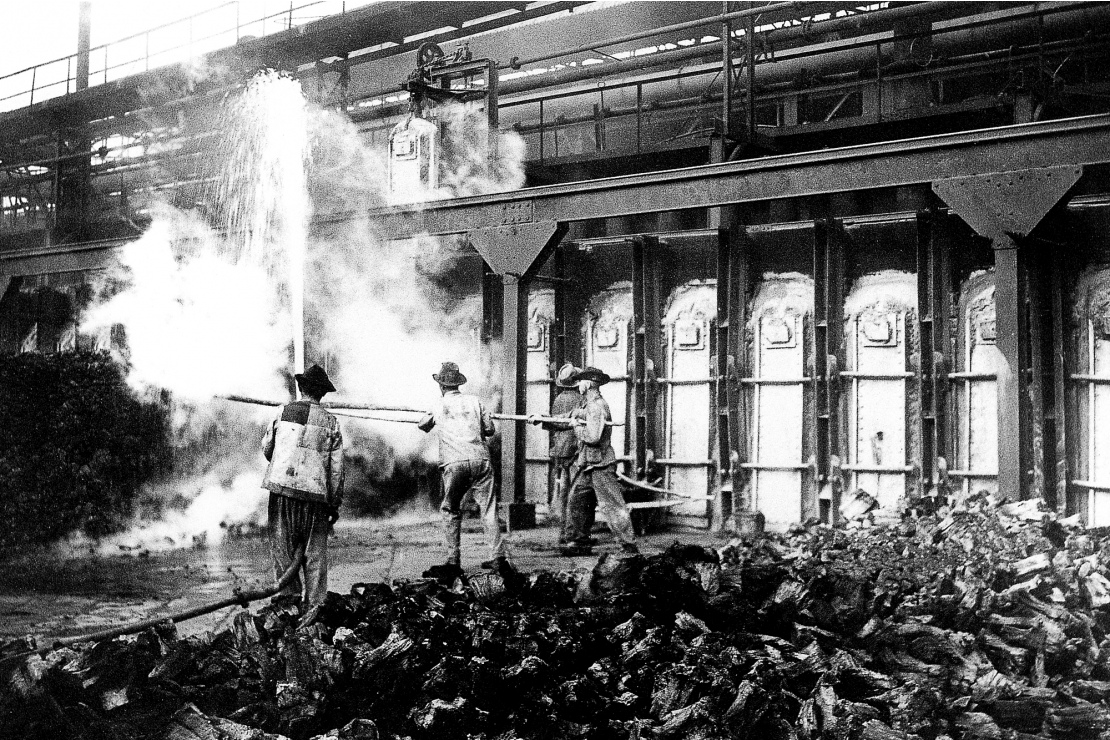

On the fields of Northern France and Belgium the First World War reached traumatising dimensions. In the course of 1916 each hectare of earth on the battlefield of Verdun was bombarded with an average of 50 tons of steel from grenades. The age of war machines was unfolding. In the forms of iron and steel, coal and coke, industry on the Saar produced the most important raw materials for Germany’s arms production. Ammunition production was the Röchling’sche Iron and Steel Works major task for German weapon production.

The Röchling’sche works also played a vital role in a special new development that emerged out of the First World War: the steel helmet. Völklingen’s newly developed induction furnace produced the best steel for the manufacture of the helmet. The works enlarged the capacity of the furnace enabling the ironworks to produce 80 to 90% of all the materials required for the steel helmet.

Hermann Röchling

Hermann Roechling Tiff

Hermann Röchling was born in Saarbrücken in 1872. He studied National Economy, Mining and Metallurgy in Heidelberg. In 1895 his father put him in charge of a blast furnace in the Völklingen Ironworks. He broadened his education in the USA and Scandinavia.

In 1905 Herman Röchling became the Managing Director of the Völklingen Ironworks whereupon he had an essential impact on the technological development of the Ironworks. As early as 1936 Hermann Röchling put the company in the service of the arms building and war policy of the Third Reich. Workforce shortage led to the closure of the ironworks in September 1939. At the end of 1939 production was running again. In October 1940 four blast furnaces were in operation. Production was switched to war materials: gun barrels, grenades and aeroplane parts.

From the early summer of 1940 forced labourers and prisoners of war were used in the Röchling works. From 1942 Hermann Röchling belonged to the High Command of the National Socialist war economy. He was one of Adolf Hitler’s greatest admirers and in his book 'Haltet die Saar' (Maintain the Saar) he praised his taking over of power and promoted it on the Saar with great enthusiasm and energy.

Hermann Röchling was convicted of war crimes at the Rastatter Trials in 1948/1949. He was released from prison in 1951.

In 1953, Hermann Röchling was awarded the Siemens Ring, the highest award for technical sciences in Germany.

Hermann Röchling died in Mannheim on 24 August 1955.

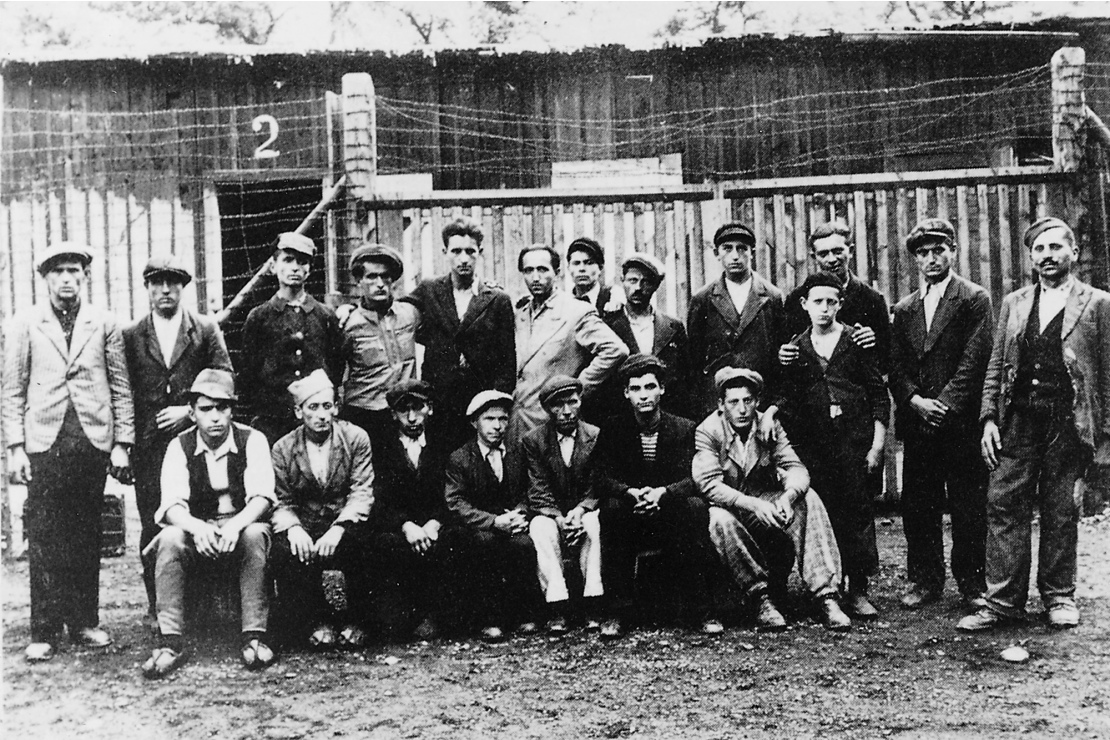

The Second World War

Franzoesische Kriegsgefangene in VK

Copyright: BUndesarchiv Koblenz

Due to its proximity to the front, at the beginning of the Second World War, the Völklingen Ironworks had to vacate its premises. On 30th January 1938, Hermann Göring appointed Hermann Röchling to the position of Wehrwirtschaftsführer (approximating a title of one of its 'war industry leaders'). The shortage in manpower led to the temporary closure of the ironworks in March 1939. However, by the end of 1939 production began again. By October that year four blast furnaces were in full operation.

Production was switched to war materials: gun barrels, grenades and aeroplane parts. From the early summer of 1940, forced labour and prisoners of war were used in the Röchling works. As the front edged ever closer, in autumn 1940 production at the Völklingen Ironworks was reduced. A skeleton staff of 2 to 3 hundred remained at the works.

Carl Theodor Röchling, Herrmann’s son and heir was murdered in the ironworks in December 1944. In the last few months of the war the Völklingen Ironworks was not spared from destruction, but the damages were actually not as great as those of other ironworks on the Saar.

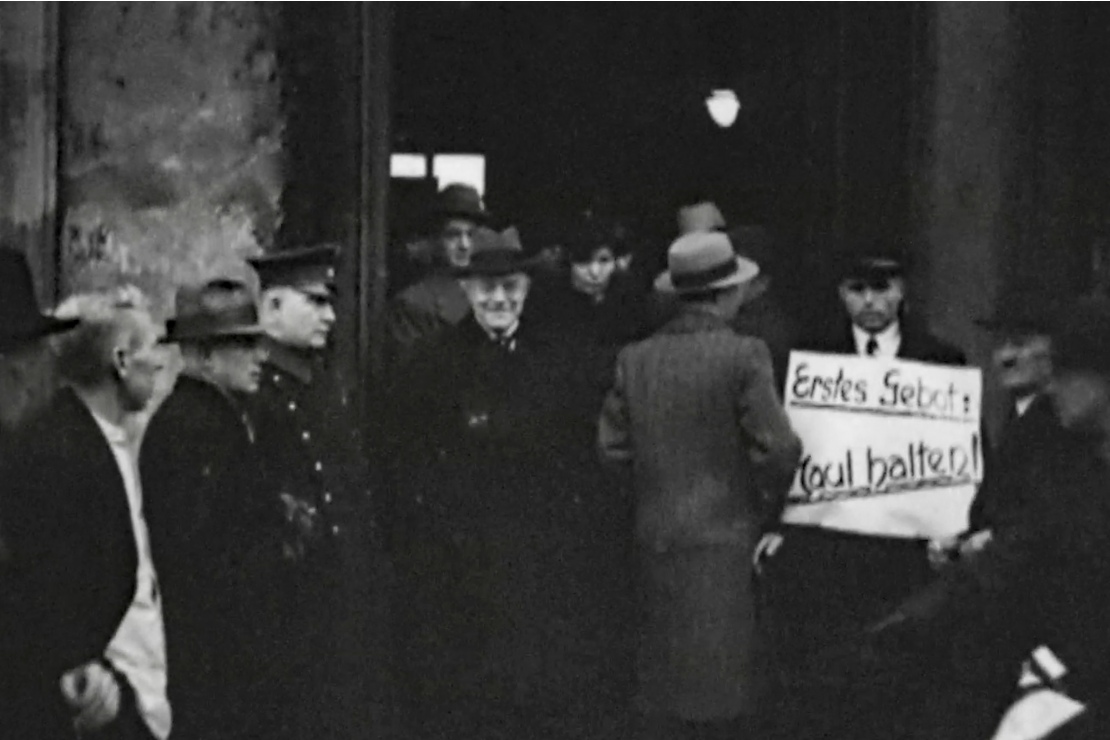

The Rastatter Trial

Rastatter Prozess

Copyright: Sammlung Ellenruth Freifrau von Gemmingen-Hornberg

From 16th February to 30th June 1948 the leading representatives of the Röchling’sche Eisen- und Stahlwerke Völklingen were prosecuted by the Tribunal Général in the castle at Rastatt: chairman of the board Hermann Röchling and members of the management executive Ernst Röchling, Hans-Lothar von Gemmingen, Wilhelm Rodenhauser and Albert Meier.

An appeal was lodged against the declared verdict of 30th June 1948. On 25th January 1949 the final judgement was announced: ten years jail, confiscation of property, loss of honour for Hermann Röchling. Three years jail, seizure of half his property and loss of honour for Hans-Lothar von Gemmingen. Wilhelm Rodenhauser was sentenced to three years imprisonment. Albert Maier’s acquittal was upheld. Ernst Röchling, acquitted in the first trial was sentenced to five years in jail, loss of honour and his property was confiscated.

The Post War period and the Economic Miracle

Roechling Wirtschaftswunder

In March 1945 the Völklingen Ironworks was occupied by American troops. In July 1945 Saarland was declared a French occupied zone. The Völklingen Ironworks came under French military administration. As early as 1952 the Völklingen Ironworks re-attained its pre-war production numbers. In 1956 French administration was lifted and the Völklingen Ironworks was returned to the Röchling family. In 1957 Saarland was integrated into the Federal Republic of Germany. The German mark replaced the French franc as currency.

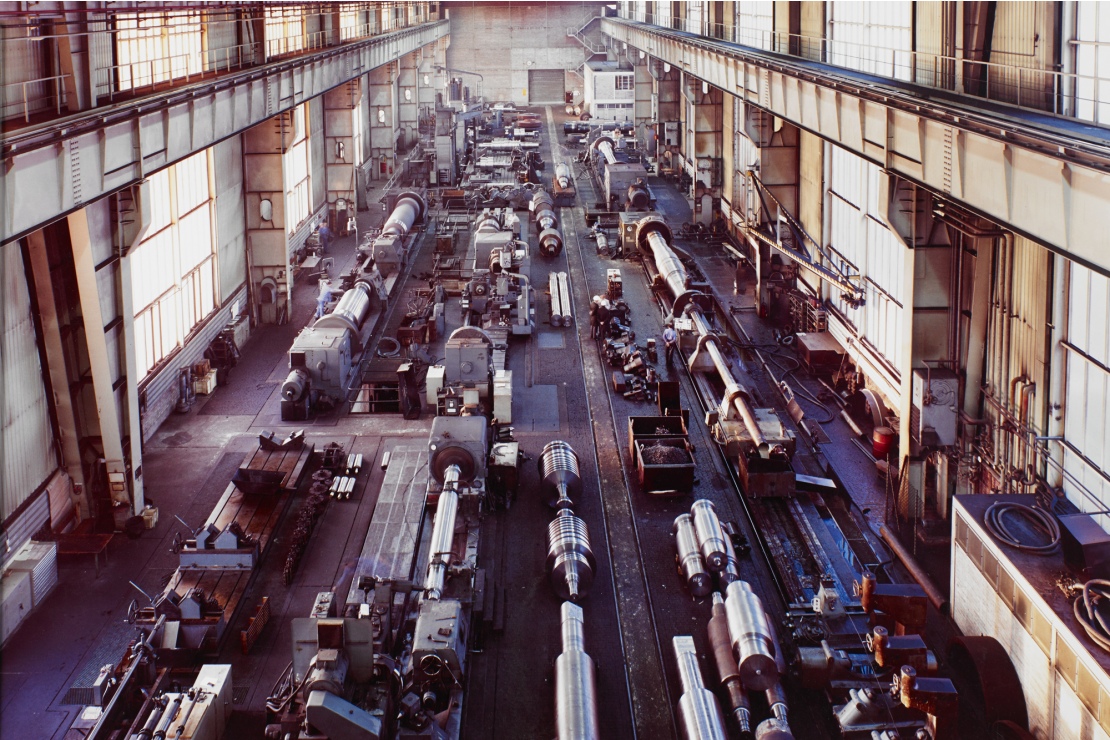

After the Second World War the construction boom brought the economic miracle to the Völklingen Ironworks evidenced by its increase in production numbers. In 1971 the Völklingen Ironworks was merged with the Burbach Ironworks to become the 'Steelworks Röchling-Burbach GmbH'. In Burbach they concentrated on the production of wire: in 1973 an extremely innovative rod mill was created – one of the largest and most modern in the world.

The Steel Crisis and Closure

Tanz auf dem "Vulkan"

Copyright: Saarstahl Archiv | Werner Schackmann

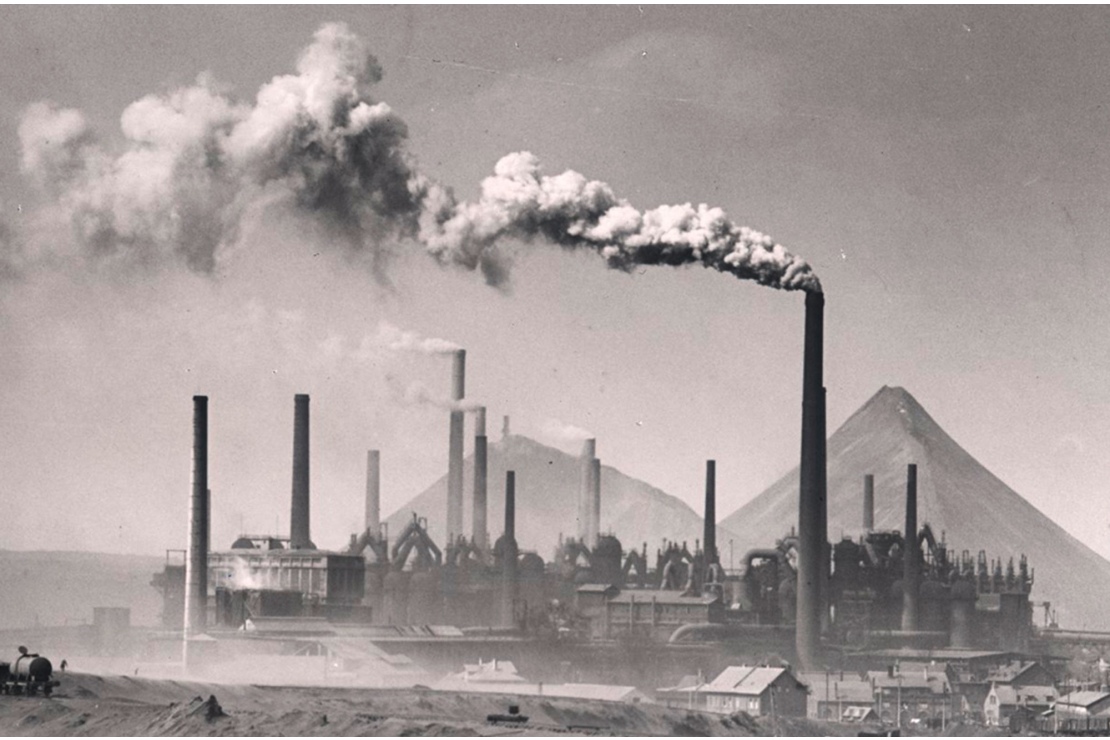

Up to the mid-1970s steel industry production numbers rose constantly. Its peak was reach in 1974. What followed was a crash: in 1975 the steel crisis had established itself. The merging of the ironworks in Völklingen and Saarbrücken-Burbach to become the 'Steel Works Röchling-Burbach GmbH' had already occurred in 1971.

In Völklingen they risked venturing further forward. In 1980 a new steel works was put into operation: the most modern technology was brought in with the hope of staving off the threat of decline. The executive management of the Steel Works Röchling-Burbach GmbH were assigned to the Dillinger Ironworks. A new company was created: 'Saarstahl Völklingen GmbH'.

The steel crisis continued worsening: 8,500 were made redundant. On 4th July 1986 the most momentous measure was taken: the blast furnaces of the Völklingen Ironworks were shut down, production of pig iron ceased, the coking plant and all auxiliary operations of iron production terminated.

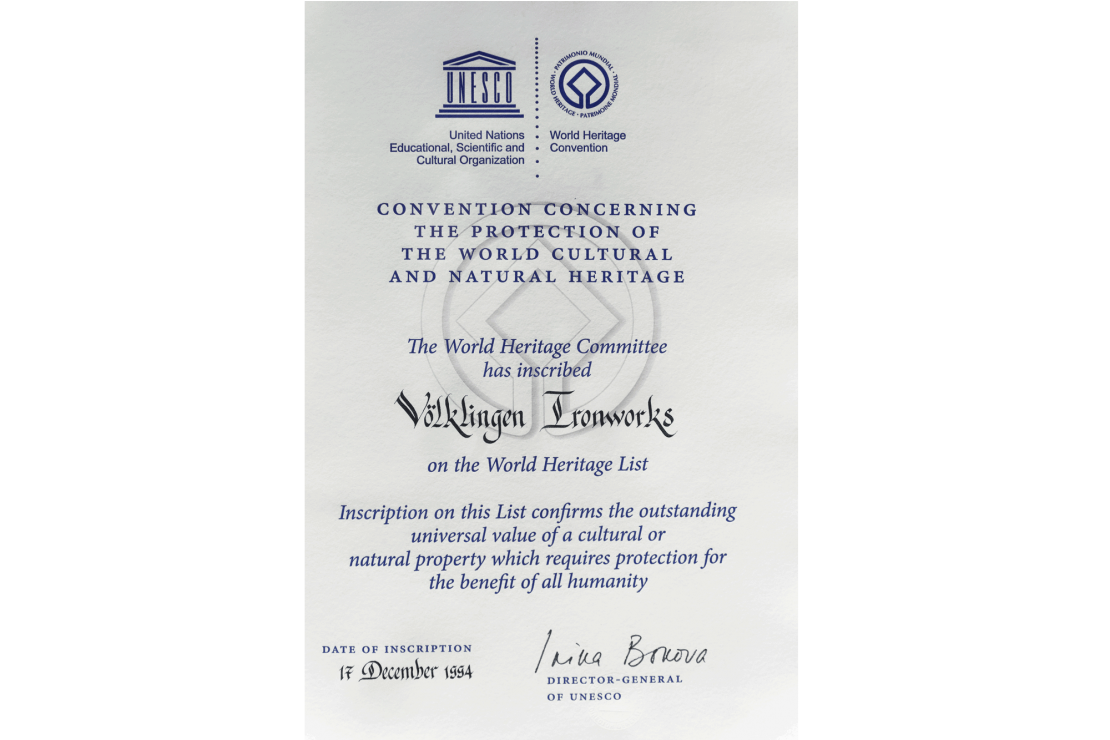

Völklinger Hütte UNESCO World Heritage Site

The Völklingen Ironworks flooded in red light

Copyright: Weltkulturerbe Völklinger Hütte | Oliver Dietze

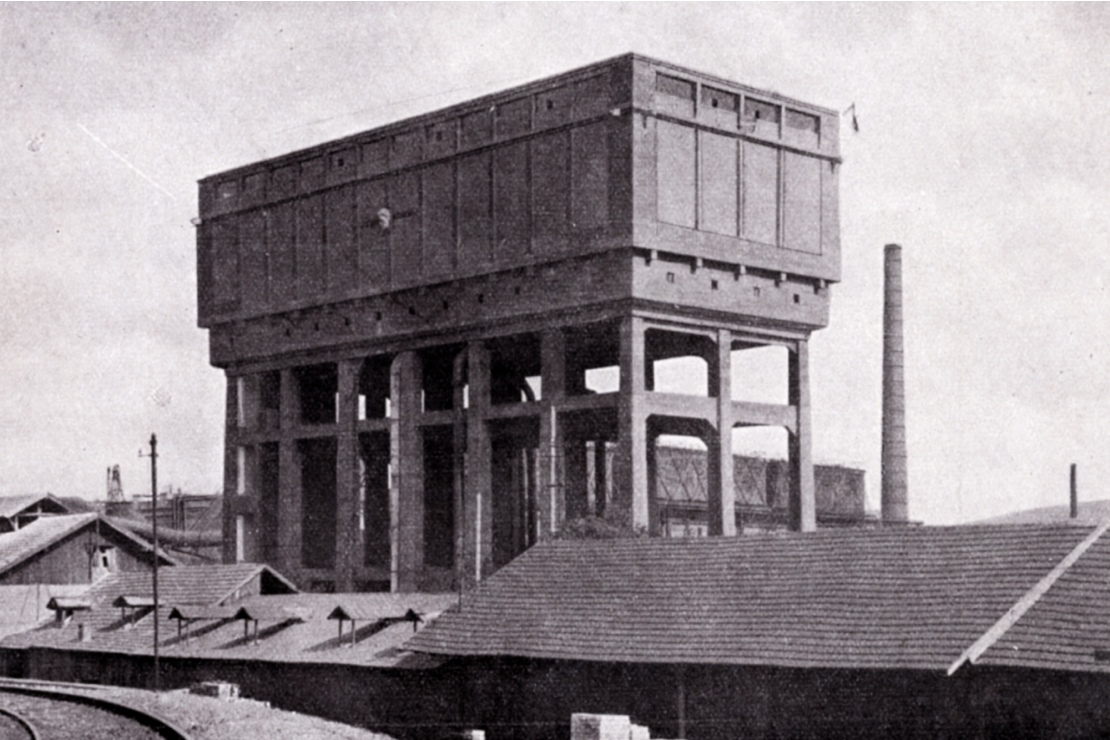

The 1986 closure of the Völklingen Ironworks changed the reality of site and its building most abruptly. Blast furnace groups, the coking plant, sintering plant, burden shed, craftsman’s alley and the blower hall were to become monuments.

The placing of a conservation order on the Völklingen Ironworks at the Saarland Preservation Department was followed quickly in 1994 with its nomination as a UNESCO World Cultural Heritage Site.